Members will be aware of the issues involving self-heating and methane emitting coal cargoes and the enclosed articles provide advice on how to avoid such situations occurring in the first place and how to deal with problems arising during the voyage.

Coal cargoes: Problems prior to and during loading

Members will be aware of the issues involving self heating and methane emitting coal cargoes, which have recently been originating from Indonesia. The logistics of dealing with coal cargoes apply to all regardless of origin.

Coal

Coal has its origins as vegetable matter which has been subjected to heat and pressure over time. It is primarily composed of carbon with variable quantities of other components and it is changes in the proportions of carbon to the other components which describes the coal rank. As the rank increases, which is as a result of the effects of increasing pressure and temperature over millions of years, so too does the calorific value. Peat is the precursor to coal and is usually considered the lowest rank as it clearly shows the remains of plants. Lignite or brown coal, is the next lowest rank followed by sub-bituminous coal which is usually dark brown to

black. Sub-bituminous coal is utilised for heating, steam-electric power generation and as an important source of light aromatic hydrocarbons for the chemical industry. Bituminous coal is a black coal and is one most people are familiar with as it is primarily used as a fuel in both open fires and in steam-electric power generation and manufacturing. It is also in coke production. The highest rank of coal is anthracite which is a hard glossy black coal primarily used for residential and commercial heating.

Most coal deposits in Indonesia are relatively young as coals go and it is the length of time available for coal formation which determines the coal rank with this process called 'coalification'. Most Indonesian coals are ‘brown coals’, i.e., lignite to sub-bitumious coal, with the rest being ‘black coals’, and many of the shipments we have seen are blended to achieve the requirements of the purchaser. Indonesian coal is known to have low dust and sulphur contents and these are very desirable properties e.g., burning low sulphur steam coal produces less sulphur dioxide. However, lower rank coals have higher volatile contents and many

Indonesian low rank coals have high resin contents both of which are undesirable. Coal reserves in Indonesia are found in various areas of Sumatra, Kalimantan, Java, Sulawesi and West Papua. The largest deposits are found in South Sumatra, East Kalimantan and South Kalimantan.

During the coal forming process, gases like methane can become trapped in the coal (and can be 'tapped off' as a resource separate from the coal). This feature represents a significant operational and transport hazard. Coal and related cargoes are fuels which undergo combustion. If coal undergoes spontaneous oxidation and the energy released by this process is trapped and not dissipated to the environment, it is known as self-heating. As a result the temperature rises and this may progress to full combustion of the coal and as a consequence stockyard and coal seam fires are well documented. Self-heating of coal can result in secondary hazards, which include the production of carbon monoxide as well as other toxic and flammable gases. In addition, any form of combustion consumes oxygen, so extreme care should be taken when dealing with coals and related cargoes as they are oxygen depleting materials. As a general rule, the higher coal rank products tend to be methane producing coals, whereas the lower rank ones are those prone to self-heating. However, in some ports, Shippers sometimes blend self-heating and methane producing coals.

Trade names for Coal:

The commercial names for some coals (often used on Bills of Lading), such as steam or thermal coal (grades of sub- to bituminous coal), and metallurgical or coking coal (bituminous and anthracite coal) reflect their end use rather than their coal rank (manufacture of steel and burning in power stations, respectively).

The IMSBC Code - COAL

Regardless of the trade name for the type of coal, there is only one COAL entry in the IMSBC Code (the “Code”), so we would expect all coal cargoes should be listed on the cargo declaration as coal. The Code provides a reasonably comprehensive set of instructions for the safe loading of coal cargoes and we would refer all parties to this entry in the Code.

Coal is usually shipped in the form of lumps, but some are very fine grained (called 'fines') and may exhibit liquefaction characteristics, hence these require further loading controls in the form of a Transportable Moisture Limit Certificate (TML) and a Moisture Content (MC) Certificate. The IMO has put guidelines in place on how shippers can monitor their moisture control methods, and the Competent Authority of the Port of Loading is now required to supply an additional certificate which details their approval of these methods.

Another coal-related cargo is listed as COAL SLURRY, and this also consists of fine coal particles, often washed off larger lumps. Since this too can liquefy, it requires a TML Certificate and MC certificate prior to loading.

All vessels intending to carry coal are required to have appropriate gas monitoring equipment for the duration of the voyage (see below).

Prior to loading a COAL or related cargo

Shippers are required to provide a cargo declaration stating if the cargo has a history of selfheating or methane emission. If it does not, ask shippers again as both these properties are common in Indonesian coals, with self-heating especially so.

All coal cargoes will require monitoring during the voyage. This will take the form of temperatures and gas readings for each hold. As indicated above, all vessels intending to carry coal are required to have appropriate gas monitoring equipment for the duration of the voyage and it is important that this equipment be in good working order with an up-to-date calibration certificate prior to the commencement of loading. Since gas monitoring is a requirement of the Code for coal and some related cargoes, it is very important to know how the ship’s gas meter works BEFORE loading starts.

Gas meters come in many different types and makes, with some having an inbuilt pump to draw the gas sample through a sampling tube inserted into the hold headspace though the gas sampling port and over the gas sensors inside the instrument. Others do not have this facility and require a rubber bulb type hand-pump positioned in-line between the end of the sampling tube and the gas meter to draw the headspace gases through the meter. Once a reading has been taken, it is also important to ensure that the meter returns to reading normal gas levels in fresh air before attempting to take the next measurement i.e. oxygen 20.9%, carbon monoxide 0%, %LEL (lower explosive level) 0%. It is also important to prevent dust and moisture from entering the gas meter as these can damage the sensors and consequently, an in-line filter is useful in this respect.

Access to the headspaces via the gas sampling ports enables assessment of the gas levels without opening the hatch covers so that oxygen (O2), methane (CH4) and carbon monoxide (CO) levels can be reliably monitored. It is also extremely important to know which gases are being checked and why:

Oxygen (O2) – this is consumed by self-heating / combustion processes, e.g., a self-heating coal should show decreasing O2 levels. Without O2 self-heating cannot occur.

Carbon monoxide (CO) – this gas is produced when self-heating or combustion occurs at low oxygen levels. This gas has no smell and is a ‘silent killer’ because it binds to haemoglobin in the blood 200 times more strongly than oxygen thereby shutting down blood oxygen transport leading effectively to suffocation.

Methane (CH4) – is a gas released by some coals, so an increasing level indicates the coal is emitting CH4 and needs to be closely monitored. If the concentration increases to reach 20% of the lower explosive limit (LEL), ventilation is required.

It should be noted that most of the commonly used multi gas meters encountered onboard ships will not be reliable for hydrocarbons or other flammable gases at low oxygen levels - in fact they will not work properly below about 12% O2 values. This is because most gas meters use combustion sensors which require oxygen to function properly and to produce reliable hydrocarbon/flammable gas readings.

Self-heating coals

The COAL schedule in the Code states that:

"This cargo shall only be accepted for loading when the temperature of the cargo is not higher than 55°C"

If the shippers' have declared that the coal has a history of self-heating then temperature monitoring of cargo will be required prior to loading (and during the voyage, see second advisory).

If shippers declare there is ‘no history of self-heating’, then prudent action would be to monitor the cargo temperature carefully and not to load any coal with temperature above 55°C. If the coal temperature is already at 55°C, then it has probably been mis-declared anyway.

The reason for having a maximum cargo temperature limit is the recognition that the selfheating reactions are like any chemical reaction in that the rate of reaction approximately doubles for every ten degree rise in temperature. Thus once coal gets to about 55°C, the rate of the self-heating reactions will be such that potentially the coal can heat relatively quickly to the point of self-ignition. Generally if the cargo temperature is below 55°C then there will be sufficient time to load the cargo, monitor it and to restrict oxygen such that the self-heating reactions are stifled and the coal cannot attain the high temperature required for ignition.

There is no provision in the Code to indicate that average values are acceptable, therefore we would advise against accepting any 'average' values for temperatures taken on barges or stockpiles.

If the coal is declared as having a past history of self-heating and/or emitting methane, this should be given in writing via the cargo declaration. These characteristics do not preclude the carriage of the coal, but dictate its handling and monitoring during loading and the voyage.

If the coal on any barge is found to have temperature in excess of 55°C then it is the responsibility of the shipper to either cool such cargo down by rotating it using bulldozers or to ensure such coal is not loaded onboard. This will require policing by the crew by way of checking temperatures regularly or local surveyors if they have been appointed. We add that it is possible to cool coal down by rotating it and/or turning it over and we in fact have had experience where this has been done effectively such that the cargo temperature was subsequently found to be below the 55°C limit and was therefore acceptable for loading.

Self-heating coals – Taking the temperature prior to loading

The Code recommends that pre-loading checks on the temperature are conducted. If shippers do not give any indication that the coal may self-heat, some may question why such monitoring would be necessary. Unfortunately there is a long history of shippers not telling the truth, or simply not realising that the information is required, or what the consequences might be for a ship in the event that the cargo self-ignites. After all, if a stockpile onshore catches fire, it is easier to deal with.

We recommend therefore that prior to loading the temperature of the nominated cargo should be checked. This may be difficult in Indonesia where much of the coal is transferred from barges, so monitoring temperatures of the cargo prior to it being transferred to the vessel will likely require the coal on the barges having to be checked.

Ideally, a thermocouple probe and thermometer should be used, but it can be difficult to push such a probe into coal. Therefore if it is difficult or none is available, then an Infra-Red (IR) thermal spot temperature device could be used. These are becoming relatively cheap so could be made available to each coal-carrying ship. However these instruments have a number of limitations, such as they are not particularly accurate and they can only record surface temperatures, so rechecking the cargo below the surface is vital, i.e., once it is disturbed by the grabs and by checking the temperature of the freshly exposed surfaces of the stow. In addition, the shippers might have temperature sensors on the loading conveyors, so these could be monitored if access is granted.

Because the monitoring of temperature may necessitate loading being stopped, it is important that the results of the cargo temperature monitoring operation are carefully recorded. Surface temperatures are a good place to start, and if these are already above 55°C (given as the maximum temperature acceptable for loading in the Code), then the cargo would appear to already be self-heating and does not meet the carriage requirements. To take further temperature readings, the stow on the barges (on stockpiles, if ashore), should be taken from within the pile, i.e., it requires digging into the pile to access the inner parts of the stow.

Self-heating can be very localised in a pile of coal, therefore many pits will need to be dug to establish the temperature throughout the whole of the stockpile/barge-load/stow. This way, a clear picture of the temperature profile of the cargo can be obtained. It may be possible to use an IR thermometer to check the freshly exposed surfaces after a grab-load is removed and if necessary stop it reaching the holds if the temperature proves to be above 55°C in the inner parts of the stow.

Methane emitting coals

Some coals emit methane, which is a highly flammable gas, so the coal entry in the Code also details the precautions needed to load and transport such material.

It is only once such coals are loaded that the monitoring for methane becomes possible, as the gas needs to be accumulated in the hold and its presence cannot be checked for in the open air.

The key to managing the risks requires understanding the nature of coal, and the management for ship transport is detailed in the COAL schedule of the Code.

Dave Myers, Fire investigator

Penelope Cooke, Cargo scientist

Nick Crouch, Cargo scientist

Coal cargoes: Problems during the voyage and at discharge

Once coal is loaded and assuming it complied with the carriage requirements of the IMSBC Code (the “Code”), i.e.,

"This cargo shall only be accepted for loading when the temperature of the cargo is not higher than 55°C"

Then the monitoring and management of the cargo during the voyage becomes important. Even if the cargo was loaded with temperatures below 55°C, this does not mean that problems will not start during the voyage.

As temperature sounding pipes are located within a hold, but at the periphery, any temperature readings can only provide a general indication of the temperature of the cargo near the pipe and will provide no information concerning what the cargo temperatures are elsewhere in the hold. Consequently, gas measurements are the preferred and most reliable method for cargo monitoring during a voyage.

Access to the headspaces via the gas sampling ports enables assessment of the gas levels without opening the hatch covers so that oxygen (O2), methane (CH4) and carbon monoxide (CO) levels can be reliably monitored. It is also extremely important to know which gases are being checked and why:

Oxygen (O2) –a self-heating coal should show decreasing O2 levels. Without O2 self-heating cannot occur.

Carbon monoxide (CO) – this gas is produced as a result of self-heating/combustion occurring at low oxygen levels. This gas has no smell and is a ‘silent killer’ because it binds to haemoglobin in the blood leading effectively to suffocation.

Methane (CH4) – is a gas released by some coals, so an increasing level indicates the coal is emitting CH4 and needs to be closely monitored. If the concentration increases to reach 20% of the lower explosive limit (LEL), ventilation is required.

It should be noted that most of the commonly used multi gas meters encountered onboard ships will not be reliable for hydrocarbons or other flammable gases at low oxygen levels - in fact they will not work properly below about 12% O2 values. This is because most are actually combustion sensors and need oxygen to function to produce reliable hydrocarbon/flammable gas readings.

Gas monitoring during the voyage:

Changes in the gas concentrations will indicate whether self-heating/combustion, or methane emission, is taking place. All vessels intending to carry coal are required to have appropriate gas monitoring equipment for the duration of the voyage and it is important that this equipment be in good working order with an up-to-date calibration certificate prior to the commencement of loading. Since gas monitoring is a requirement of the Code for coal and some related cargoes, it is very important to know how the ship’s gas meter works BEFORE being faced with an emergency situation. Please see first advisory for further details on gas meters.

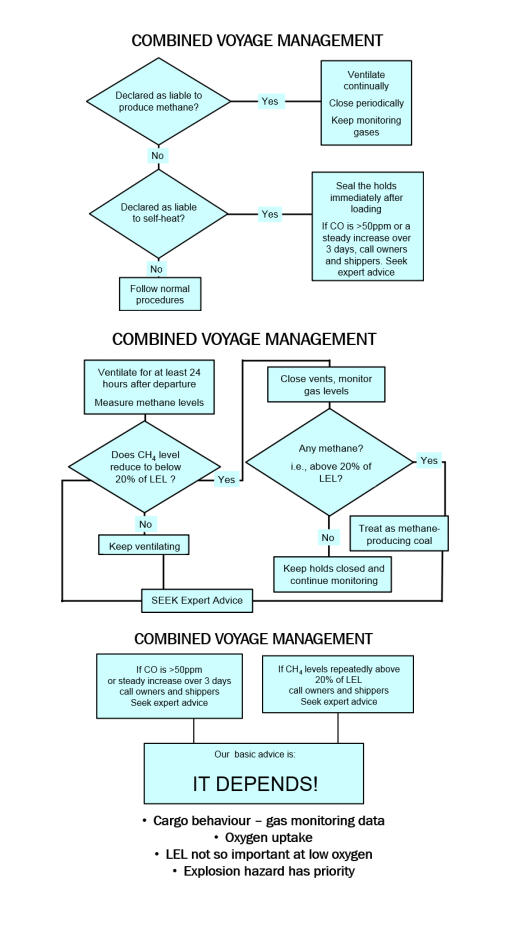

During the voyage

Having loaded a Code-compliant coal, the shipment should be monitored for gas variations during the voyage. The Code indicates that if there is no declaration of any hazards such as self-heating or methane emission, then the holds should be ventilated for the first 24 hours. During this time, the gas in the headspace of the holds should be monitored and this will require the ventilation to be stopped for a suitable period (the Code recommends this is not less than four hours) prior to the gas readings being taken. Assuming no methane is detected or if it is, it remains at very low levels, then the holds should be sealed and gas monitoring continued.

Self-heating coals

Self-heating/combustion will be evident if high (and increasing) CO levels are detected in combination with decreasing oxygen levels. If the CO increases but the oxygen does not decrease, then this indicates that the holds are not sealed effectively. If necessary, Ramneck tape and expanding foam should be used to assist with the sealing of the holds, but these can only be used as a last resort because cargo holds are not designed to be gas tight.

The Code indicates that CO levels above 50 ppm are an indication that the cargo may be selfheating. Even when sealed and oxygen supply is restricted, the CO levels in the headspace above a self-heating coal could exceed 500 ppm (some gas meters cannot measure levels above this, so the actual value may be higher). The CO levels should 'level out' as the oxygen is used up and as long as no methane is detected (or if the methane levels remain below the limits in the Code, see next section), then the holds should remain sealed until each hold is ready to discharge.

If gas levels indicate self-heating is taking place the only thing which can be done is to limit the amount of oxygen available in the holds. Since self-heating/combustion requires oxygen, if the holds are sealed then the oxygen level should fall to the point where further combustion is prevented from occurring.

Methane emitting coals

Methane and other flammable gases are often emitted from coals. The reaction of coal with oxygen results in self-heating/combustion and can also release flammable gases from the coal possibly generating an explosive atmosphere, although in our experience this is quite rare.

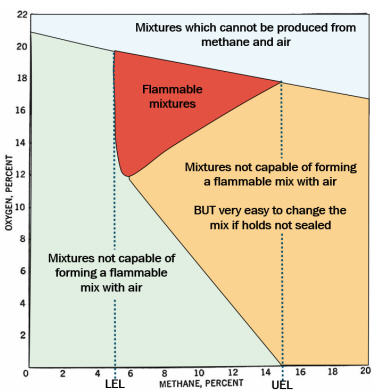

In the reaction between methane and oxygen, twice as much oxygen as methane is required for the “perfect match”, and since the oxygen content of air is about 21% by volume, then the amount of methane required for the most violent reaction is around 10%. Mixtures of between 5 to 15% methane in air are explosive mixtures. While sealing the hatches and stopping ventilation should control or restrict self-heating/combustion, if the coal starts emitting methane or other inflammable gases, then these may require removal in order to prevent development of a potentially explosive atmosphere. In this situation, the only option would be to open the vents but we would strongly recommend seeking expert advice in this situation.

To assist with safety assessments, it is important to know what the lowest explosive limit or LEL is for a given gas mixture. For methane, the LEL is 5%, i.e., the lowest amount of methane mixed with air that can be explosive. However, for safety reasons, the IMSBC Code COAL entry states that the amount of methane in a hold, which is considered as the trigger point for action by the master, is 20% of the LEL - therefore this is actually equivalent to only 1% methane in air (volume by volume). The gas concentrations should be monitored and a record kept, since their levels will determine the advice given by an expert. If oxygen levels drop and stay low, even if methane levels are high, then there is unlikely to be an explosion. However, if methane is above 20% of LEL, then ventilation may be advised.

After Coward H.F. and Jones, G.W. (1952). Limits of flammability of gases and vapours; US Bureau of Mines, Bulletin 503: 1-155.

After Coward H.F. and Jones, G.W. (1952). Limits of flammability of gases and vapours; US Bureau of Mines, Bulletin 503: 1-155.

Hazard management – which to choose?

Explosion – stop methane build up - Ventilate

Combustion – restrict oxygen access - Don’t ventilate

COAL fires on ships

Usually fires in coal are small and rarely become 'raging infernos'. However, they do tend to produce lots of smoke and toxic gases. If the coal or related cargo appears to be on fire adding lots of water to a hold fire is not a practical option. The added weight of the water may damage the ship by over stressing the hold plating (stresses and bending moments will need to be considered). Equally impractical is that to discharge a hold full of dirty, contaminated, and potentially acidic water is going to be difficult and expensive due to environmental concerns. Unless all the cargo is fully submerged, it will not usually put the fire out.

However, water can be used to cool the grabs used for the discharge and help control the smoke by dowsing the smouldering/burning areas so that once the majority of the cargo is removed, flooding the remaining amount to extinguish the fire might be an option. Bulldozers and their drivers cannot be put into a hold to move the cargo to allow access for the grab if the air or the cargo is too hot, the air in the hold is lacking oxygen, and/or has unsafe carbon monoxide levels. It is likely to be very impractical if not impossible to find stevedores who are trained to operate and discharge cargo in full breathing apparatus.

Coal and related cargoes may produce acidic liquids which may corrode metal structures. It is therefore necessary to check the pH of any water in bilge wells.

If the ship is still at sea, the main logistical challenge will be to stop oxygen entering the holds. An alternative option may be to use inerting gas such as carbon dioxide or nitrogen but these may not be available or may not be available in sufficient quantity. Seek expert advice if considering the use of inerting gases. Boundary cooling of the external parts of the hold will at least cool the coamings and deck surface and so assist with access. If sealing the holds to starve the fire of oxygen does not work, the only option will be to discharge the cargo.

Discharging a 'problem' Coal cargo.

The main problems associated with discharging a self-heating cargo of coal are associated with the fact that even for a small localised area of smouldering, burning coal, a considerable amount of smoke will be generated. This smoke accumulates in the headspace of the hold and will be released en-masse when the hatch covers are opened thereby appearing to make the situation worse than it really is. In our experience this frequently causes undue concern with the Receivers and has resulted in some coal terminals refusing to discharge the cargo despite the fact that it was the hatches being opened which introduced fresh supplies of oxygen into the cargo holds to support continued self-heating/combustion. We recommend therefore that the hatch covers are only opened when there is agreement to discharge the cargo directly. Until that point, they should remain firmly sealed such that exposure to oxygen is restricted.

The best way to deal with such a situation is to have the area of smouldering or burning cargo removed but obviously this requires the area to be accessible and for it to be safe, in terms of carbon monoxide levels, to enter the hold to remove it. Localised spraying of fresh water to dampen down such areas is recognised as a temporary solution but excessive use of water should be avoided since any significant increase in the moisture content of the cargo will reduce the calorific value of the coal somewhat. In addition, if the hot area isn’t removed but remains exposed to oxygen then it is likely to re-ignite within a matter of hours or days. Any water used for firefighting should be fresh water rather than seawater if at all possible since Receivers rarely tolerate chloride contamination as it can potentially cause corrosion to the power station boilers when the coal is ultimately burnt.

In terminals where the coal is discharged to conveyor lines, Receivers and Terminal Operators may be reluctant to put hot coal onto their belts for fear of damaging them i.e., melting the rubber, or worse, setting fire to them. Since coal fired power stations are dependent upon a continuous supply of coal, damage which renders the conveyor system inoperable for any length of time will be of real concern to the Receivers, despite the likelihood of such damage occurring being remote. In addition, the use of water in firefighting can also affect the cargo handling properties of some coals and when wetted, they may become 'sticky' and difficult to discharge onto conveyor lines.

Once discharge of a self-heating coal cargo commences it is important that the holds are discharged completely and in a timely manner since part discharged holds have a larger reservoir of oxygen in them with which to feed the self-heating reactions in any remaining cargo stow. This can cause ignition or re-ignition of 'hot spots' within the stow. Obviously whether or not the Terminal suspends discharge for any reason is likely to be beyond the control of the Master and crew but there have been a number of cases where part discharged cargo holds ignited whilst the vessel waited at the anchorage for completion of discharge. If such a situation arises, all that can be done is to attempt to restrict exposure of the cargo to oxygen as much as possible by closing all the ventilators etc., and for the monitoring of the headspace gases to continue. Providing the vessel has done all that it can to prevent self-heating within the stows by restricting exposure of the cargo to oxygen throughout the voyage, then ignition of the cargo during discharge, if it does occur, is beyond the control of the vessel and simply due to the inherent nature of the coal. Unfortunately though, this will not always prevent claims against the vessel.

Finally, Receivers may also take issue with the smoke produced from burning coal, partly as this may restrict stevedore access to the holds, and partly due to the environmental impact. Care should be taken to ensure that once discharge starts (in a problem coal) that it is completed, and that partly discharged holds are not left open.

When discharging hot, methane emitting coal and related products, additional care will be required because the opening of the hatches will allow oxygen to enter the holds and when mixed with the methane could potentially result in an explosion. Ensuring there are NO ignition sources around the holds and the hatch cover wheels are greased should reduce the possibly of sparks igniting the methane and oxygen mixture. Seeking expert advice will be critical prior to starting the discharge process.

Initially, it may be suggested that the gases are vented off via the hatch cover vents however this allow oxygen to enter the holds. Equally, it may be advised that an inerting gas is pumped into the hatches just prior to opening. This will reduce the risk of an explosion occurring by flushing out the flammable gases via a second open vent. This should only be considered with expert advice.

Having fire fighting personnel on standby may be required to both assist in the event of an incident as well as to spray the cargo with water once it is onshore. Spraying a small amount of fresh water onto the area of concern may enable this patch to be removed by the grabs. However, once the discharge has reached the limits of the grabs, then the gas levels may restrict personnel e.g., the bull dozer driver, from entering the holds.

Dave Myers, Fire investigator,

Penelope Cooke, Cargo scientist and

Nick Crouch, Cargo scientist

The Association is grateful to Messrs. Brookes Bell for contributing to this article.