February 2017

In this article, Kate Li of Skuld Offshore looks at the insurance aspects of vessels and units entering into lay-up, while Egil Legland of the American Bureau of Shipping (ABS) provides an overview in relation to the technical aspects. ABS has in addition kindly allowed us to re-publish excerpts from their Lay-up Guide.

Impact of the downturn

2016 was a devastating year for most owners in the offshore service sector and many analysts predict that this will continue at least through 2017. Although market ups and downs are not unknown in this sector, this downturn is by some way the deepest since the 1990s, with the oil price having fallen as low as USD 27 a barrel in January 2016. The impact of this on owners in the offshore service sector has been enormous. Strong competition in an already overly crowded market has driven the charter hire down drastically. The OSV day rate has dropped by at least 40% from early 2014 and utilization rates have plunged across the industry.

More and more owners are now resorting to the option of stacking their out of work vessels to reduce operational costs. This can then lead to a slightly reduced (but not removed) exposure from a P&I risk perspective as, depending on the type of lay-up chosen (discussed in more detail below), the machinery may no longer be running, there may be fewer or no crew on board and the vessel is not operating in the offshore field.

Continuing risk

Although the risk may be generally reduced, it would be unwise to think that there is no risk at all, as many things can and do still go wrong while the vessel is in lay-up. Obviously, it is crucially important, particularly during tough market conditions, to properly protect owners from the risks they may face so that they are not unnecessarily exposed.

Over the last six months, we have seen almost the full spectrum of P&I claims from vessels and units which are both hot- and cold-stacked.

-

Collision

Breaking mooring lines and dragging anchors can cause vessels or units to collide with other fixed or floating property. In a lay-up situation, there are typically numerous other proximate units and vessels, and of course port facilities including quays, jetties and cranes. On the other side, owners still run the risk of their vessels or units being struck and the possibility of the other ship limiting their liability may expose the innocent owner to a significant unrecoverable amount.

-

Pollution

Pollution may be caused by grounding, contact with other property or technical circumstances such as leakage from malfunctioned valves, garbage disposal, corrosion and anti-fouling. When there are fewer or no crew on board, these things may not be so readily observed. -

Wreck removal

Owners face a substantial risk in relation to wreck removal liabilities if the vessel or unit is involved in a casualty while stacked. - Crew

When crew remain aboard, crew risks remain.

Managing idle rigs

When the decision is made to stack rigs, some owners decide to take them out of service and leave them unmanned, while others retain a skeleton crew onboard to carry out maintenance and upkeep activities. Both decisions have positive and negative consequences. An unmanned rig saves the owner money because there is no need to crew the vessel. That gain, however, can be offset by significant loss if the integrity of the asset suffers over time, requiring more work at the back end to get it ready to return to service. A laid up rig with personnel onboard can be maintained so that its condition and onboard systems are kept up, but having a crew working on the asset carries an associated cost.

There are a number of considerations that need to be taken into account when an asset is going to be laid up. The environmental conditions in the area are a critical concern. If an asset is not in a safe location, it can be subjected to weather elements that can result in fatigue and damage. Other criteria for choosing a site include such things as year-round water depth and site stability for anchors.

Regardless of the decision, lay-up requires proper guidance so exposure to risk can be minimized, and the time and cost for reactivation can be reduced.

Insurance requirements

It is important that vessel owners involve their insurers at an early stage and ideally prior to the planning phase of the lay-up.

« Depending on the lay-up type, insurers will require different information to ensure that the underwriting takes account of the change in risk. »

For example, insurers would normally not require a lay-up plan for an MOU in standby mode with full crew on board. For all other idle modes, the general rule is that a lay-up plan shall be prepared and followed by the assured, and approved by the insurers. The insurers shall be advised if there are any changes to the lay-up plan or arrangements during the lay-up period, or if the MOU is to be moved temporarily or permanently.

How Skuld can help

At Skuld Offshore we recognise the pressure our assureds are facing in today's difficult market and we are always looking at ways in which we can provide support. Our team of underwriters are happy to discuss with owners the prospect of lay-up covers which are specifically tailored based on an assessment of the particular circumstances.

In addition, increasing numbers of shipyards are looking for lay-up insurance for their new build vessels/units which have been fully constructed but not yet delivered. This is something that Skuld Offshore has substantial experience in providing. For further details on this, or other covers, please contact a member of the Skuld Offshore Team.

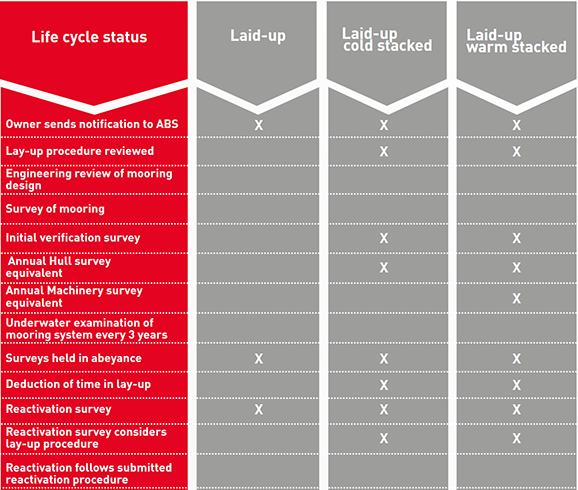

The different types of lay-up

A laid-up unit or vessel is one that is out of service for an undetermined length of time. There are mainly two categories used; warm stacked(1) and cold stacked(2)

Lay-up procedure requirements

If vessels are to be reactivated later, it is not the case that they can be laid up by simply being powered down and left. If laid-up in accordance with class standards, the classification society will have a number of requirements. Some of the most important requirements of ABS are noted below, but owners should always check with their own classification societies as to their exact requirements:

- On Warm stacked units there must be a sufficient number of qualified personnel available onboard in order to maintain full-time fire, leakage, moorings and security watch of the unit as required by the flag administration.

- On Cold stacked units there must be an alarm system fitted for fire, bilge flooding, loss of power, loss of station, and any other items deemed appropriate.

- All the unit's fire safety equipment including emergency fire pump are to be proved in good order.

- Self-contained breathing apparatus and flotation escape equipment are to be provided and maintained immediately available for the watchmen or lay-up crews.

- All ventilators and air intake or exhaust openings are to be adequately covered. Supply and exhaust openings for necessary emergency diesel generator or fire pump engines are to be arranged for immediate or automatic opening. All fire dampers are to be freed-up and then secured in closed position. All fire division doors are to be closed and appropriate signs to be posted or painted on the doors to confirm the doors are kept closed during the lay-up period.

- Effective and reliable means of communication to be provided for contact with firefighting, tug and rescue facilities, or central security base. A secondary communication system is to be provided in the event of failure or damage to the primary means.

- A source of power for providing emergency lighting, fire extinguishing water, and bilge pumping throughout the unit is to be immediately available. Emergency sources of power are to be suitable for marine use.

- The proposed engine is to be suitable for marine use.

- Hazardous drains, drain tanks, spaces, and piping systems containing drilling hydrocarbons are to be flushed, cleaned, and gas-free as applicable.

- Machinery space bilges are to be dry and cleaned of all debris, oil, or other flammable products.

- Fuel and lube oil tanks are to be wired or locked closed at the tank valve except where required for the emergency power supply engine.

- All valves to or from the sea on floating units are to be wired or locked closed except those actually required for use during lay-up.

- Hot work (i.e., welding or burning) is not to be permitted during lay-up except under specially supervised safety control.

- The unit is to be readily accessible and approachable for shore-based or floating firefighting and other emergency equipment at all times and tides.

- In the event of an emergency tow from lay-up while in deactivated condition, a towing pendant is to be available.