Course of events

During routine inspection of the chain locker with chain, one member of an inspection team fainted during the inspection and died shortly after.

A second member fainted during the rescue operation, but recovered.

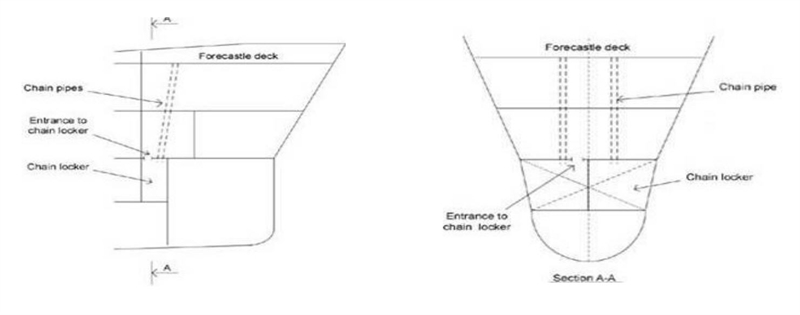

One member had entered the chain locker through a manhole on deck and had started the inspection approximately 2 metres below the deck. The chain locker is of the rectangular type and the chain rests on a perforated bottom above the bottom of the locker, see enclosed figure. The other two members of the team remained on deck. After a few minutes the person in the chain locker was observed lying apparently unconscious in a corner. A second member of the team then immediately went down to rescue and sent the third member of the team to call for assistance. During this first attempt of rescue also the second member of the team fainted.

First aid was given as soon as the two men were brought out of the chain locker and on the way to hospital. The life of the member who first entered the chain locker could, however, not be saved.

Extent of damage

One person killed.

Probable cause

The immediate cause of this tragic accident was lack of oxygen in the chain locker, probably caused by the on-going corrosion process over time and the stagnant atmosphere in the chain locker.

The manhole for the chain locker had been opened some hours prior to the inspection but the cover had been put loosely on again in order to prevent anyone to stumble into the locker. The chain pipes leading to the locker had been made temporarily tight by cement in order to keep seawater out. The anchor had apparently not been used the last 4-5 years.

The locker appeared to be clean and painted and the chain was found without extensive corrosion. However, some corrosion was found at the bottom of the chain locker, including some remaining water.

The oxygen content of the atmosphere in the chain locker was measured shortly after the accident and found to be far below acceptable limit.

It is estimated that the person who suffered this fatal accident was exposed to the atmosphere in the chain locker for approximately 10-15 minutes.

Lessons to be learned

- Inspection of spaces such as chain lockers, cofferdams etc. may represent similar dangers as inspection of ballast tanks with respect to dangerous atmosphere and should be carried out with the same care.

- Enclosed spaces are to be properly ventilated and verified safe to enter prior to entry. Means of forced ventilation should be applied as necessary, also during inspection.

- Atmosphere should be monitored also during inspection by means of portable meter giving audible alarm in case of unsafe atmosphere.

- A team of two persons should carry out inspection of enclosed spaces. A safety watch of at least one person should be stand-by at the entrance to the space with means to communicate with the inspection team inside the space as well as with the duty responsible officer on board in case of emergency.

- Rescue equipment including breathing apparatus should be kept readily available at the space entrance in case of emergency.

- The oxygen content in a normal atmosphere is 20.94% by volume. No entry to enclosed spaces should be performed unless the oxygen content is close to this value.

- Companies carrying out inspections on board ships should review their personal safety instructions in light of the above.

Please Note: No indications or pre-warning can be felt in situations with low oxygen content giving risk of suffocation!

Source: Det Norske Veritas