Cargo damage due to water ingress through leaking hatch covers remain a frequent cause for cargo claims. Maintaining hatch covers in a weathertight condition is accordingly very important and there is also a statutory requirement for weathertightness in the International Convention on Load Lines, 1966:

"Weathertight means that water coming from the weatherside (e.g. sprays, rain, green seas) will not penetrate through any openings and so enter the hull of the ship, even in the worst sea and weather conditions likely to be encountered by the ship in service".

Ultrasonic testing (UST)

Testing of vessel's hatch covers for weathertightness can be performed by different methods. The most common ones are hose tests and Ultrasonic Tightness Tests. Tightness can also be checked by light test, chalk test and air test. However, UST is the only way to generate a measurable result, which is necessary to decide whether the tightness condition of hatch covers is acceptable.

UST should be carried out by qualified surveyors. Surveyors must complete an UST operational course to familiarize with UST and hatch covers and obtain an ultrasonic operator certificate. Ultrasonic equipment is calibrated by an authorized company or manufacturer. The assigned surveyors must be able to present their UST operator and calibration certificates.

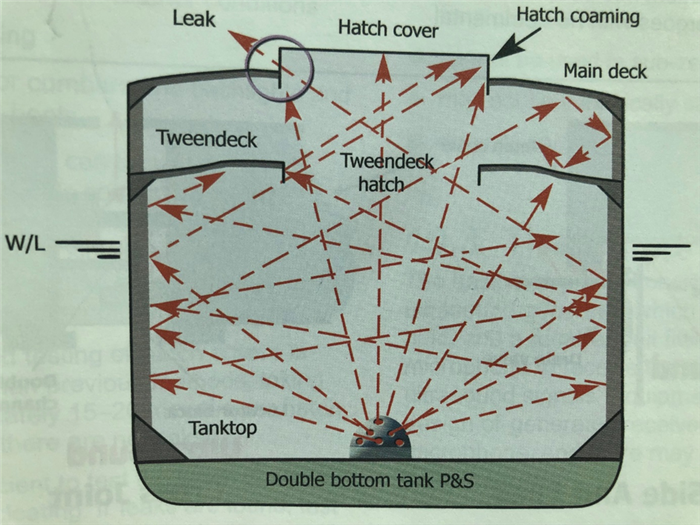

Ultrasonic equipment uses sounds with frequency above 20 KHz that cannot be heard by the human ear. The ultrasonic emitter (which is generating ultrasound) is placed in the cargo hold and then activated. The UST operator will check for ultrasound signals passing through the rubber packing and compression bar interface of the hatch covers and record them in the report.

In view of the good track record, P&I insurers accept UST as it provides measurable and reliable results. This is because UST returns information on the compression status of the sealing which, in turn, indicates the capacity of the packing rubber to compensate for relative movements between the panels and the hatch coaming (as well as in between adjacent panels) which is crucial in preventing water ingress. Any discontinuity in the seal (e.g. missing or damaged rubber packing) or area with lack of compression (e.g. wavy or deformed compression bar) will allow ultrasound to pass and the leaky spot being identified as an area of concern.

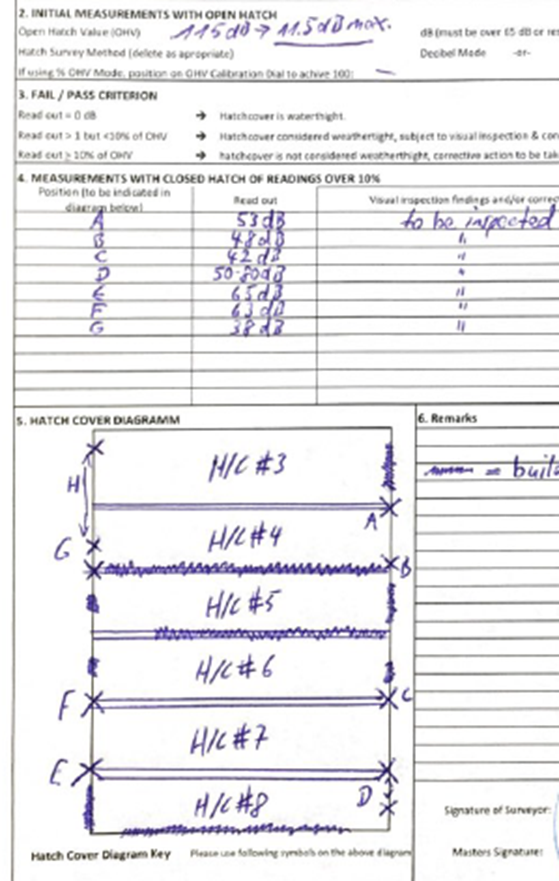

The acceptable range of leakage is less than 10% of the open hatch value (OHV). If the hatch covers' leakage is more than 10% of the OHV, the club may insert a warranty in the certificate of entry. All claims arising out of leaking hatch covers will not be reimbursed by the club until the warranty is lifted. Members need to repair the hatch covers in line with the makers guidelines and good industry practice and request the club to arrange a follow up UST.

As pointed out above, UST provides information about the tightness of the hatch covers. However, it is important to ensure that under all conditions, a tight seal can be achieved and maintained whilst the vessel is at sea. This requires a few hatch cover key parts (such as, but not limited to, bearing pads, locators, stoppers) to be in a good condition.

Therefore, the attending surveyor should make sure that all key parts of the hatch covers are in good technical condition which requires a detailed visual inspection. Only after obtaining results of both the ultrasonic tightness test and visual inspection of hatch covers (against the maker's criteria) the attending surveyor can conclude whether the hatch covers are weathertight or not.

Avoid high expansion foam and sealing tape

High expansion foam and sealing tape are commonly used to ensure weathertightness of vessel's hatch covers.

However, for P&I Clubs, the use of high expansion foam and sealing tape indicates that the owners are aware of the potential leakage of the hatch covers. If the cargo receivers present such evidence, ship owners would be in a weak and disadvantageous position in cargo claim negotiations. High expansion foam and sealing tape also can give a false sense of security as it can be washed away by waves or become damaged as a result from relative movements between the panels and coaming.

P&I clubs recommend owners to avoid using high expansion foam and sealing tape. The hatch covers should be well-maintained and its weathertightness should be ensured without additional measures.

Skuld is grateful to Walter Vervloesem (FNI) of the IMCS Group for having contributed to this article.